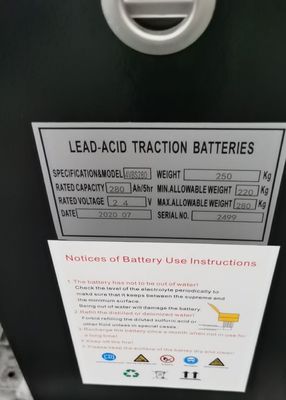

Traction Battery 24v 280AH Perfect Connection For HELI CDD16/20 Electric Stacker

280Ah / 5hrs 24V Forklift Traction Battery Durable Environmentally Friendly

| Type |

Forklift Battery |

| Application |

Electric Forklift Truck |

| Standard |

BS standard |

| Width of cell |

158mm |

| Technology |

Tubular Positive Plates |

| Model |

24V 4VBS280 |

| Cell Quantities |

12 cells |

| Cell Voltage |

2V |

| Connection Type |

Flexible/Soft connection |

| Steel Tray Size |

648*248*548mm |

Product Strength

1. High quality flooded lead-acid battery

2. >= 1500 times cycle life.

3. High performance tubular positive plates

4. Meet IEC 60254 standard.

5. CE,ISO9001 and ISO14001.

6. Lower distilled water consumption

7. Environmental and healthy

8. Nice design and good quality

9. Easy to use and durable

10. Low current recharge

11. Competitive price

12. Wooden case packaging

13. Automatic watering system and Agitation system.

14. Larger and thicker plate means less internal corrosion

Trouble Shooting

There are many reasons of the cells’ troubleshooting, except for the quantity and the storage, operating wrongly and unmerited maintenances are also one of the most important reasons.

If you find troubleshooting, analyze the reasons in time and take effective measures to eliminate it.

The features of the familiar troubleshooting and the reason and the methods of checking and repairing are as following:

1. Internal short-circuit

1.1 Symptoms

The charge voltage is always lower than normal; the discharge capacity is lower than normal; the discharge voltage quickly reduced to the final voltage; the voltage and the specific gravity raise slowly, and less or without gassing at the end of charge; the temperature of the electrolyte is high and raise faster during charge; the self-discharge is serious.

1.2 Probable causes

There are many reasons for short-circuit: conducting materials enter the cells connecting the positive and negative plates; the separator is damaged; the plates give birth to the lead bulb and store at the ear of the plates making short-circuit; the active materials are expanded or shed, the sediment touch the bottom of the plates leading short-circuit.

1.3 Possible remedy

First check if there are conducting materials entering the cells, if there are, remove the conductors. Remove the plates group checking if the lead-bulb expend leading short-circuit, if it is, removes the lead-bulb and change the electrolyte. If the separator is damaged, separate the plates group and find the damaged one and change to a new one.

2. The reversible vitriolic salt of the plates

2.1 Features

The discharge capacity is reduced and the specific gravity is lower than normal; during charge, the initial and the final voltage is higher than normal; the gassing appears too early and the temperature of the electrolyte raise fast and easy to exceed 55℃; voltage reduces too fast when discharge and reduces to the final voltage too early.

2.2 The reasons of troubleshooting

The cells are often weakly charged or not equalizing charged in time or often over-discharging or small-current discharging, in the station of half-discharging or discharging for a long time, or the level of the electrolyte is too low and some other reasons make the vitriolic lead in the positive and negative plates hard to transform into the active materials.

2.3 The ways to solve the problem

For the cells of plates with vitriolic salt, if it is not serious, you can revert by proper over-charging; for the serious ones, you can charge with the small current; for the most serious ones, you can deal with them by using hydropath. For the sake of protection from it, you should operate according to the service manual and take equalizing charge in time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!